Rubber Bellows

Rubber & Fabric Bellows

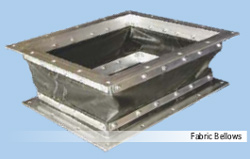

We manufacture Fabric Expansion Joints made up of various rubberized

fabrics to perform better and give maximum performance against heat,

cold or ambient environment. Kiran™ expansion Joints are normally

compatible with most of the applications ranging from different

temperatures, media and operating conditions with very minimal

adjustments to suit the functionality of the Industry.

We specialize in manufacturing customized solutions as per the

customer's requirement depending on the Size, Shape, Temperature&

Pressure. Kiran™ offers preassembled units for your new projects or

your repair works, this is the best solution for a quick on-site installation.

All the raw material used in the manufacturing of Expansion Joints are

quality tested and recommended by our technical team based on their

extensive research and knowledge of manufacturing expansion joints.

The material composition to manufacture the Expansion Joints is

carefully analyzed on the basis of application, medium, pressure &

temperature.

We manufacture Fabric Expansion Joints made up of various rubberized

fabrics to perform better and give maximum performance against heat,

cold or ambient environment. Kiran™ expansion Joints are normally

compatible with most of the applications ranging from different

temperatures, media and operating conditions with very minimal

adjustments to suit the functionality of the Industry.

We specialize in manufacturing customized solutions as per the

customer's requirement depending on the Size, Shape, Temperature&

Pressure. Kiran™ offers preassembled units for your new projects or

your repair works, this is the best solution for a quick on-site installation.

All the raw material used in the manufacturing of Expansion Joints are

quality tested and recommended by our technical team based on their

extensive research and knowledge of manufacturing expansion joints.

The material composition to manufacture the Expansion Joints is

carefully analyzed on the basis of application, medium, pressure &

temperature.

| Applications: | Materials: | ||

|

• Oil Tanks • Cement Plants • Petro Chemical Refineries • Steel Plants • Boiler Plants |

• Thermal Power Stations • HVAC Units • Water Supply Pipes • Industrial Chimneys • Industrial Blowers, and Suction Pipes etc. |

• Silicone Coated Fibre Glass • Nitrile (NBR) • Natural • Neoprene |

• Hypalon • Fibre Glass • Polyurethane • Butyl Coated Fabrics etc. |

Air Springs

Kiran™ air springs are superior quality products, designed and built for durability, performance, and value. Through strict design parameters, Kiran™ air springs operate dependably in the toughest conditions and in many types of industrial applications. You'll know you have chosen an air spring brand that you can trust, one that stands for reliability and striving for your complete satisfaction. With quality built into every Kiran™ air spring (air bags), they are made to last. Bellows air springs have one, two or three convolutions in the flexible member. There are two styles of bellows:

Kiran™ air springs are superior quality products, designed and built for durability, performance, and value. Through strict design parameters, Kiran™ air springs operate dependably in the toughest conditions and in many types of industrial applications. You'll know you have chosen an air spring brand that you can trust, one that stands for reliability and striving for your complete satisfaction. With quality built into every Kiran™ air spring (air bags), they are made to last. Bellows air springs have one, two or three convolutions in the flexible member. There are two styles of bellows:

• Crimped Design

• Sleeve Type

With the crimped design, the end retainers are permanently attached by mechanically crimping the retainer around the built-in bead wire of the flexible member.

Sleeve type bellows offer similar characteristics to the crimped design bellows, but, as with the sleeve type rolling lobe the flexible member is constructed without internally molded bead wires. The end retainers are permanently attached by pinching the flexible member between the end retainers and external crimp rings which are then swaged to the proper

diameter.Sleeve type bellows offer the lowest force to compress of any type of air spring.

Applications:

• Lift springs for lift axles on trucks and trailers

• Ride springs for trucks and trailers

• Actuators and isolators for industrial application

Our primary function is to design and manufacture custom sizes as per client specifications, drawings or even samples. Apart from custom sizes we are also involved in manufacturing standard sizes and stocking most of them for easy transactions.